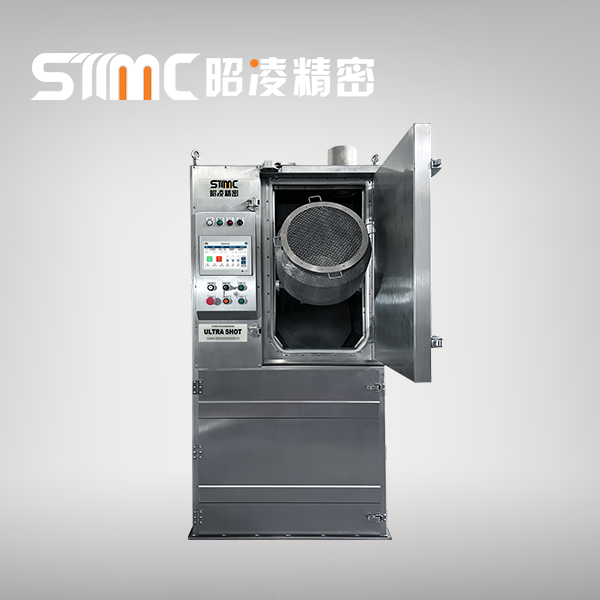

Automatic rabara tiiso cryogenic deburring mochini Ultra Shot NS-60T

Pontšo e qaqileng

Cryogenic deflashing mochini 60T

Cryogenic deflashing mochini 60T

Karolo ea mantlha ea mochini oa cryogenic deflashingdikgetho

Kenyelletso ea Sehlahisoa

Theknoloji e tsoetseng pele

1. Foreimi e feletseng ea tšepe e sa hloekang e tiisa bophelo bo bolelele ba mosebetsi oa mochine.

2. Baskete e entsoeng hantle e phahameng e nang le tsamaiso ea OBD e bonahatsa ka botlalo bokhoni bo phahameng, ho boloka matla, ho sireletsa tikoloho.

3. Taolo e mengata ea polokeho ho netefatsa ts'ebetso e bolokehileng le e tšepahalang.

Tsamaiso e matla

1. Sisteme ea matla e sebelisa lebili la tšepe le matla a phahameng le li-motor tse tsoang kantle ho naha tse tsoang kantle ho naha tse sebetsang ka 60/45 degree inclined cylindrical basket.

2. Matla a matla le matla a ho sebetsana le lihlahisoa a fihla tekanyo e tsitsitseng ea 1: 1.

3. Karolelano e nepahetseng ea matla e hlahisa ho nepahala ho sa tloaelehang ha ts'ebetso.

Sistimi ea ho hlopha

1. Mochini o amohela mofuta oa Sato oa anti-plugging, o fetolehang oa 3D o feto-fetohang skrineng se sisinyehang sa waveform.

2. Ts'ebetso e ntle ea ho kenya mocheso oa mocheso ho thibela ho qhoqhoa ka ntle.

3. Ho qhaqha ka potlako le ho bonolo le tlhokomelo, ho ntlafatsa katleho ea tlhahiso.

4. Bophelo bo bolelele ba ts'ebetso bo nang le botsitso bo phahameng.

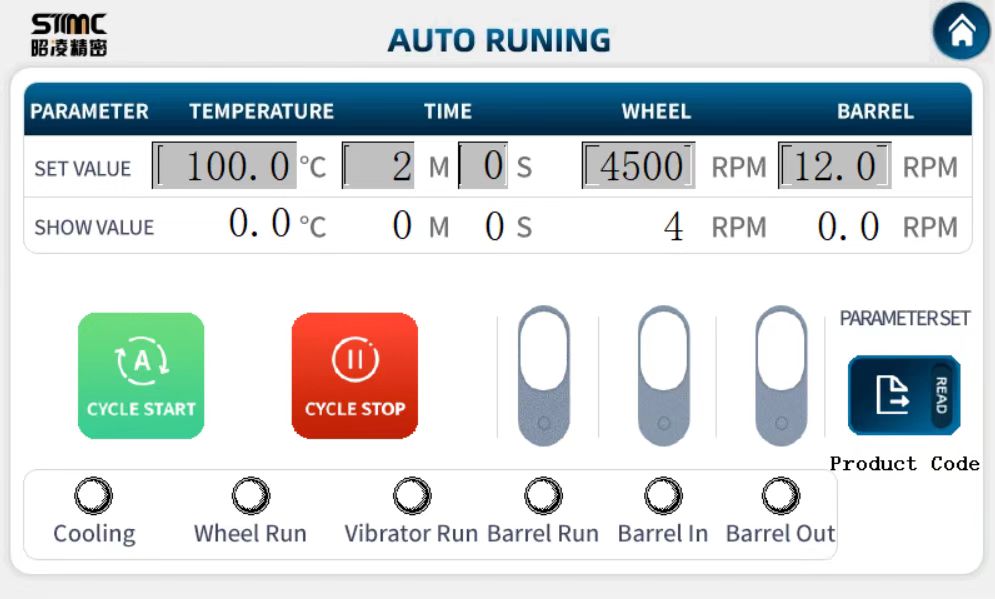

Sebopeho sa Software se sebetsang

Skrine sa lapeng

Skrini e kholo e sebetsang

Mokhoa o itekanetseng

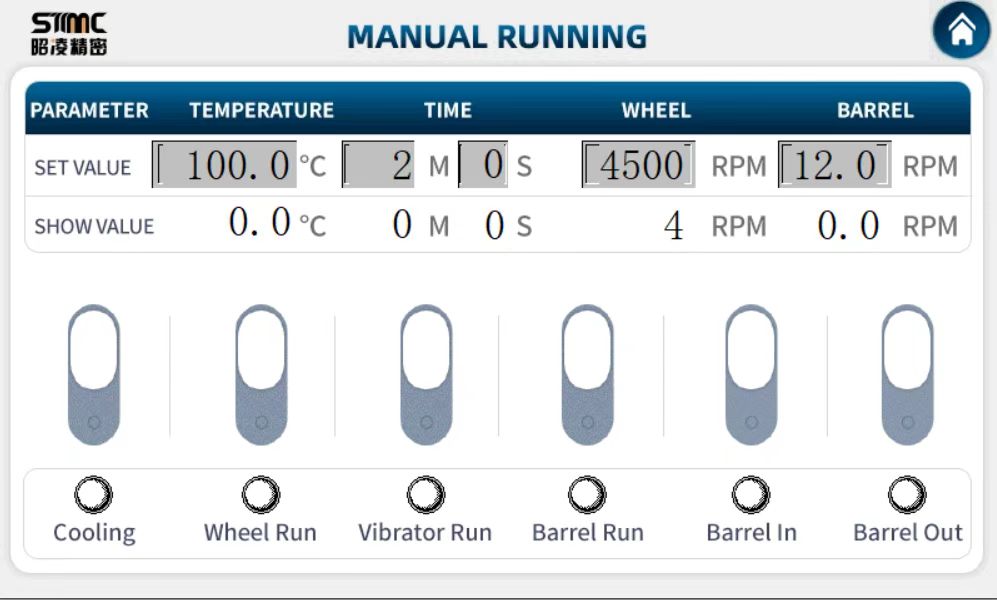

Mokhoa oa ho sebetsa ka letsoho

Paramethara Boloka / Bala

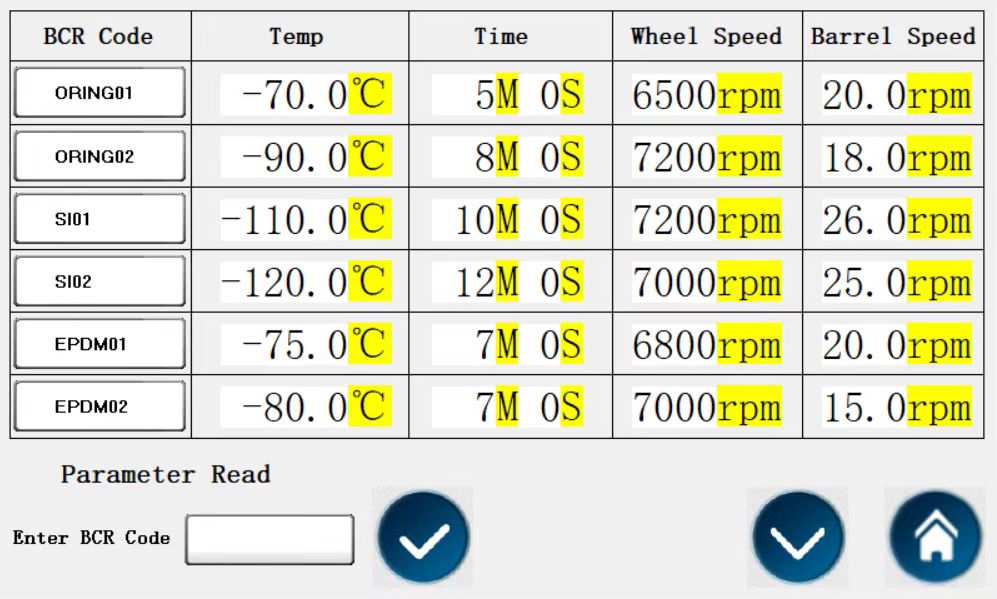

Laeborari ea Parameter

Kopo

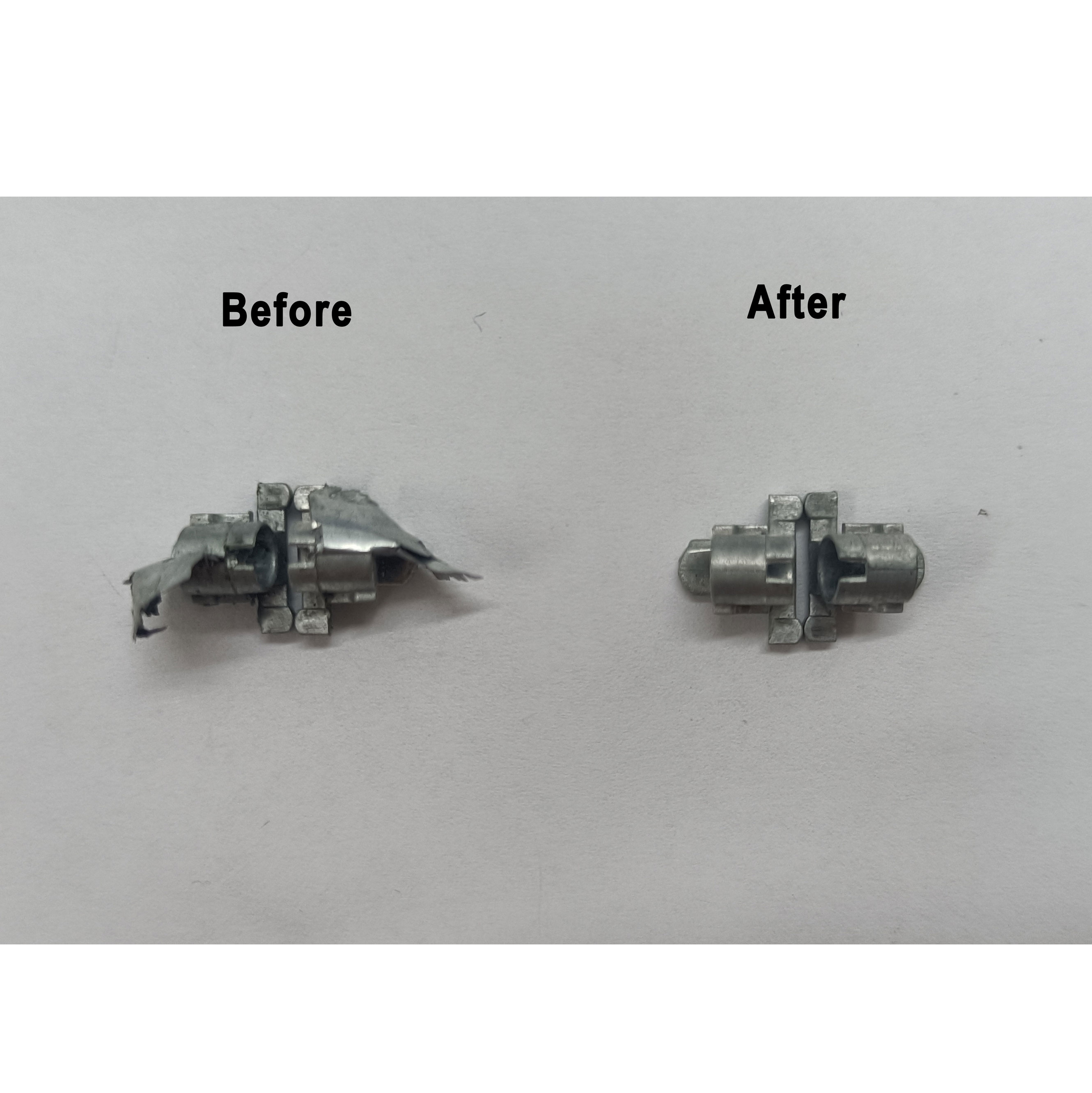

Mochini oa cryogenic deflashing o fa basebelisi tharollo ea ho sebetsana ka katleho le khanya ea sehlahisoa, e loketseng haholo bakeng sa tlhahiso ea bongata bo boholo, likarolo tse nang le boholo bo sa tšoaneng, mehaho, kapa thepa e hlokang ho nepahala ho phahameng bakeng sa phekolo ea holim'a sehlahisoa.

1. Rabara le likarolo tsa polasetiki.

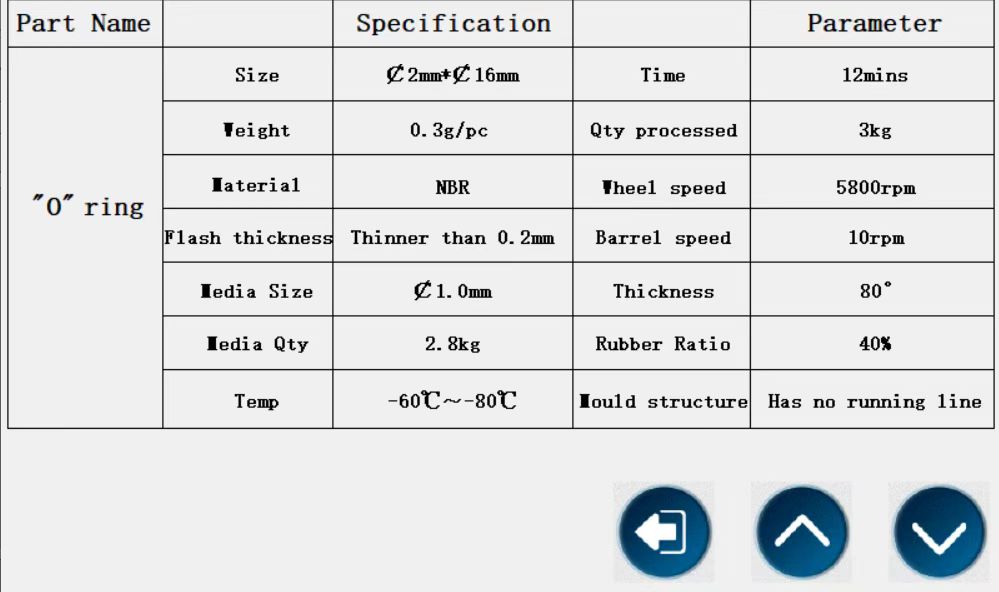

2. E ikhethang e loketseng masale a 'O'.

3. Ho tlosoa ha Flash ea lihlahisoa tsa thepa ea elastic.

4. Likarolo tsa elektronike.

5. Lisebelisoa tsa bongaka.

Mokhoa oa Cryogenic deflashing hangata o sebelisoa indastering ea likoloi, sefofane, bongaka, lisebelisoa tsa elektroniki le indasteri ea rabara e akaretsang.

Molemo oa STMC

1. Tšimoloho ea lihlahisoa

E tsoa ho Sehlopha sa Japane sa Showadenko lilemo tse 30 tsa pula ea thekenoloji, lilemo tse 16 tsa boiphihlelo ba tlhahiso ea lapeng.

2. Litšenyehelo tsa tlhōlisano

Ts'ebetso e ntle haholo ea ho kenya letsoho mochesong e fokotsa litšila tsa naetrojene ea metsi.PIR insulation layer e nang le ts'ebetso e ntle ea ho kenya mocheso le mocheso o tlase oa solenoid valve ho fokotsa litšila tsa naetrojene ea metsi le litšenyehelo tsa ts'ebetso.

3. Ba hōlileng tsebong botekgeniki tharollo

Litlhaloso tsohle tsa tekheniki li entsoe ka nepo ho kenyelletsa lebelo la projectile, angle ea projectile, sebopeho sa baskete, sekhutlo sa tšekamelo le ho potoloha, jj.

4. Ts'ebetso e sebetsang haholoanyane

Likarolo tse ka hare ho tsamaiso ea potoloho ea projectile li tiisitsoe hantle tse etsang hore tsamaiso ea projectile e be matla le ho potoloha ho tsitsitseng haholoanyane.

5. Tšireletso e tšepahalang ea tšireletso

Thepa e khethehileng ea lemati mochining e ka mamella khatello ea 0.5Mpa.STMC e sebelisa molamu o khethehileng oa mamati o tsoang kantle ho naha ho tsoa Japane mefuteng eohle ea mochini oa cryogenic deflashing o sa nolofatseng feela ho buloa ha kamore empa hape o bolokehile le ho fokotsa ts'ebeliso ea naetrojene ea metsi.

6. Likarolo tsa mantlha tsa tlhophiso e phahameng

Likarolo tsa mantlha tsa mantlha li romelloa ho tsoa Japane tse nang le ts'ebetso le boleng bo holimo, li ka nkeloa sebaka haeba ho khethoa tlhophiso ea Sejeremane, ho kenyeletsoa li-motors tsa Siemens (boikhethelo), frequency converter, PLC le touch screen.

7. Tsamaiso ea boleng

Tsamaiso ea boleng ba ISO9000, tlhahlobo e kenang e fetang 800, tlhahlobo ea likopano tse 30, le tlhahlobo ea 25 ea phano.

8. Tshebeletso e tletseng

Teko ea mahala ea thekiso ea pele le ho fana ka tlaleho ea tlhahlobo (ho kenyeletsoa le litlhahiso tsa tokiso ea ho bopa), fana ka tharollo e ntle ka ho fetesisa ea tekheniki, waranti ea selemo se le seng (ho fihla ho lihora tse 2000), likarolo tse setseng tsa netefatso ea phepelo ea lilemo tse 10, karabelo e hole ka nako e ka tlase ho lihora tse 2, lihora tse 48. tšebeletso ea setšeng, maeto a ho boela a 4 ka selemo.