Mochini o ikemetseng oa O-ring cryogenic deflashing Ultra Shot NS-180C

Pontšo e qaqileng

Mochini oa cryogenic deflashing 180C

Mochini oa cryogenic deflashing 180C

Sehlopha sa Ts'ebetso sa NS-180C

Kenyelletso ea Sehlahisoa

Theknoloji e tsoetseng pele

1. Foreimi e feletseng ea mochini oa tšepe e sa hloekang e tiisa bophelo bo bolelele ba ho sebetsa.

2. Baskete e entsoeng hantle e phahameng e nang le tsamaiso ea OBD e bonahatsa ka botlalo bokhoni bo phahameng, ho boloka matla, ho sireletsa tikoloho.

3. Tšebelisano ea mochine oa motho ka skrine ea ho ama.

4. Potso ea alamo le ts'ebetso e sa sebetseng hantle e ka thusa basebelisi ho fumana mathata a mochini kapele ka tlhaiso-leseling e hlakileng le ho rekota ho rengoa ha lifate ka mokhoa o ikhethileng, ka hona ho thusa ho boloka mochini kamehla le ho netefatsa hore mochini o lula o le maemong a matle ka ho fetisisa.

5. Tataiso ea ts'ebetso ea mochini o hahelletsoeng ho thusa basebelisi ho khutsufatsa nako ea ho ithuta ea mochini.

6. Tataiso ea ho rarolla mathata e hahelletsoeng, e ka fanang ka tataiso ho thusa basebetsi le basebetsi ba tlhokomelo ho fumana bothata.

Tsamaiso e matla

1. Sisteme ea matla e sebelisa lebili la projeke ea tšepe e matla haholo (boikhethelo ba mabili a projectile a mabeli) le enjene e tsoang kantle ho naha ea Majapane e sebetsang ka 60/45 degree inclined cylindrical basket (basket e khethehileng e fumanehang ka boikhethelo).

Sistimi ea ho hlopha

1. Mochini o amohela mofuta oa Sato oa anti-plugging, o fetolehang oa 3D o feto-fetohang skrineng se sisinyehang sa waveform.

2. Ts'ebetso e ntle ea ho kenya mocheso oa mocheso ho thibela ho qhoqhoa ka ntle.

3. Ho qhaqha ka potlako le ho bonolo le tlhokomelo, ho ntlafatsa katleho ea tlhahiso.

4. Bophelo bo bolelele ba ts'ebetso bo nang le botsitso bo phahameng.

Kopo

Ultra Shot 180 series cryogenic deflashing machine e fa basebelisi litharollo tse sebetsang bakeng sa ho sebetsana le li-flange tsa lihlahisoa, tse loketseng haholo bakeng sa tlhahiso ea bongata, likarolo tse kholo kapa lihlopha tse hlokang ho nepahala ha phekolo e phahameng.

1. Silicone insole.

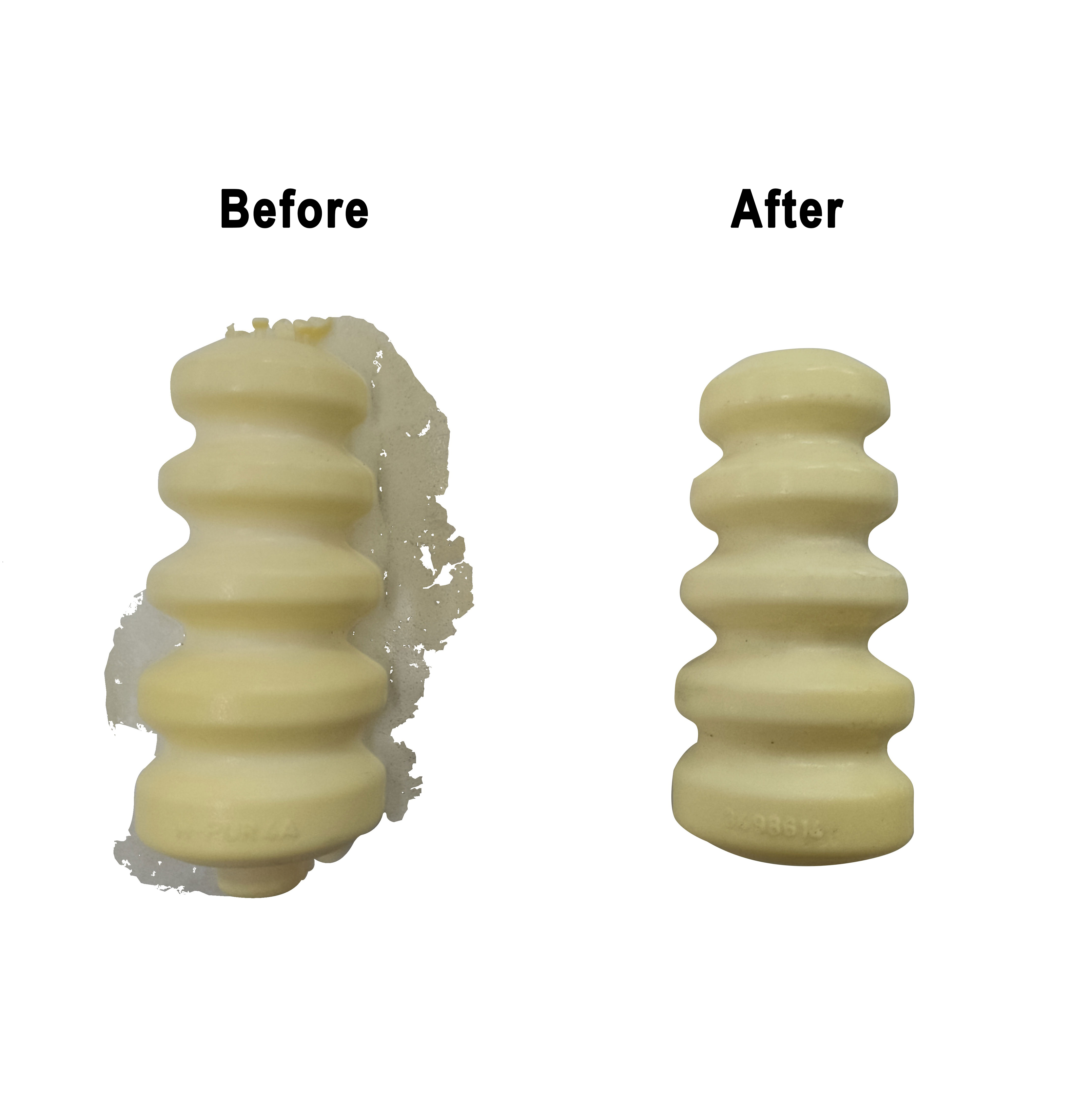

2. Ho lokisoa ha moeli oa damping block.

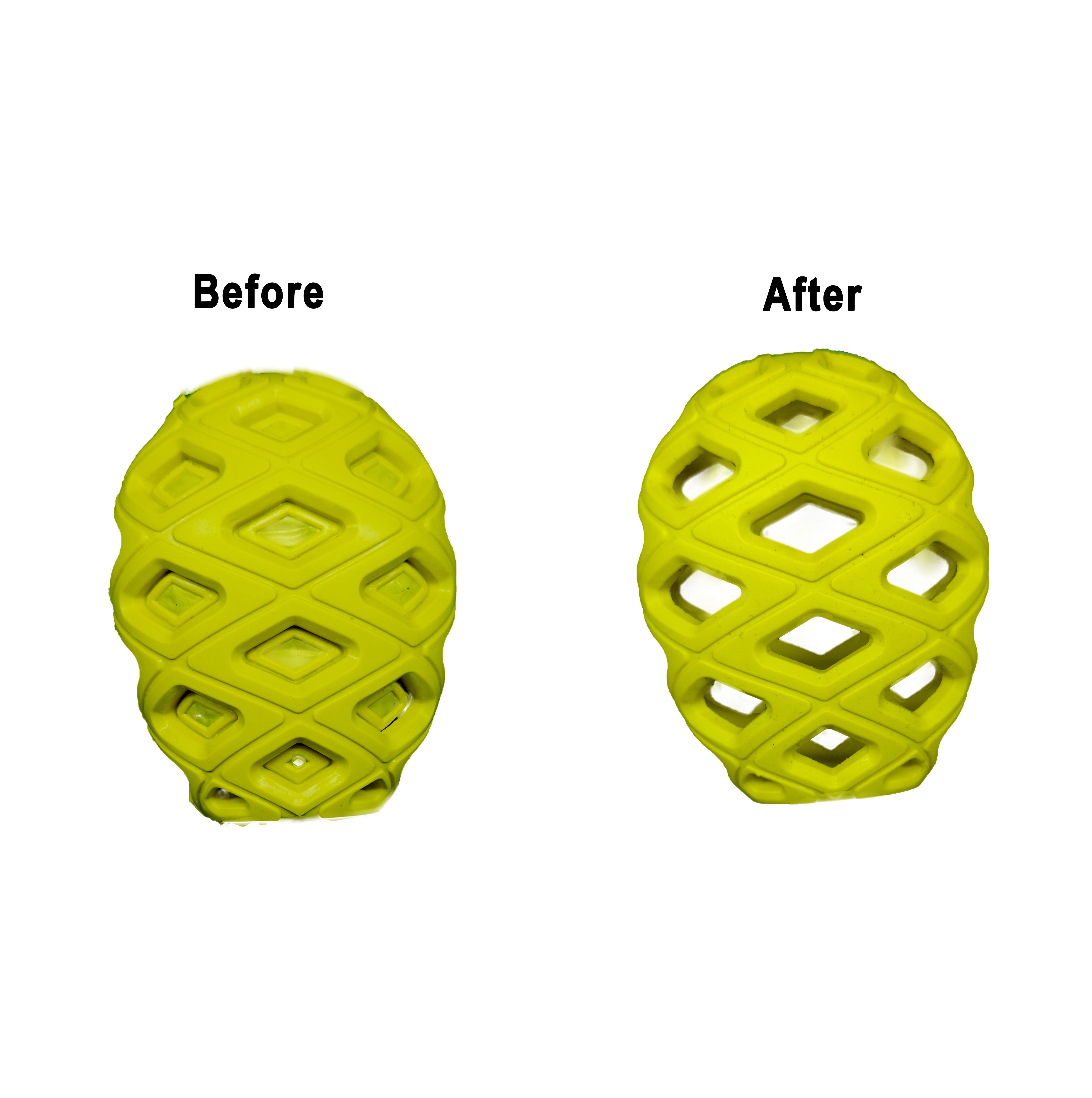

3. Lihlahisoa tse kholo tsa thepa ea elastic.

Boemo ba OEM

Bakeng sa bareki ba itokisetsang ho etsa kopo ea cryogenic deflashing, STMC e ka fana ka tlhahlobo ea ts'ebetso le tlaleho ea tlhahlobo ea litsebi bakeng sa lihlahisoa tse fapaneng le ho fana ka moralo o sebetsang & motheo oa moralo holima boemo ba sebaka sa marang-rang.

STMC e khona ho hlophisa baenjiniere ba nang le boiphihlelo ho fana ka koetliso ea litsebi sebakeng sa marang-rang le tataiso ea botekgeniki bakeng sa basebelisi ba bareki mabapi le ts'ebetso e bolokehileng, ts'ebetso ea paramente, tlhokomelo ea letsatsi le letsatsi le ho thunya mathata.

STMC e na le litsi tsa ts'ebetso ea cryogenic deflashing sebakeng sa Bochabela (Nanjing), sebaka se ka Boroa (Dongguan) le sebaka se bophirima sa China (Chongqing) ho fana ka liteko tsa cryogenic deflashing le lits'ebeletso tsa OEM.

Ka nako e ts'oanang, STMC e fana ka ts'ebeletso ea ho nchafatsa le ho ntlafatsa mochini ho mefuta e fapaneng kapa litlhaloso tsa mochini oa cryogenic deflashing e le ho thusa bareki ka ntlafatso ea ts'ebetso ea mochini.